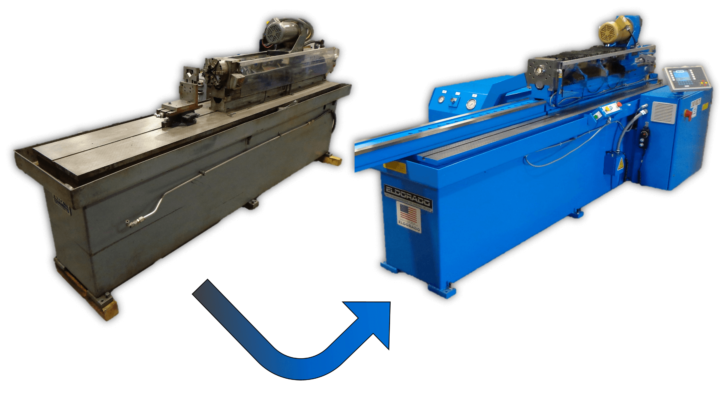

Used/Rebuild

Factory Rebuilds and Retrofits

Kays Engineering offers factory rebuild services for all DeHoff, Eldorado, and TechniDrill machines. By refurbishing your used machine, you get the performance and reliability of a new machine without the new machine price.

All full rebuilds offer the newest control options as retrofits and employ the latest technologies, which enables Kays Engineering to offer a 12-month warranty on all factory rebuilds, the same as our new machines.

Machine Rebuilds

Machine rebuilds can include any of the following, depending on customer needs:

Machine Component Replacement

- Re-grind the Slide Ways

- Re-machine and hand-scrape Gibs and Straps

- Replace and hand-scrape Chip Box

- Spindle Test and Break-in

- Full re-paint

- Spindle Bearings

- Spindle Motor

- Spindle Lube System

- Spindle Drive Belts

- Ball Screw and Bearings

- Rotary Coolant Union

- Hoses and Fittings as needed

- Spray Shields and Bellows

Electrical Component Replacement

- Latest Machine Control featuring Beckhoff components

- Variable Frequency Drive

- Encoder Feedback Servo Drive System Motor

- Motor Starters

- Wiring

- Electrical Enclosure

Coolant System Component Replacement

- New High Pressure Pump

- Rebuild High Pressure and Transfer Pump Motors

- Replace all wiring, Hoses, and Fittings as needed

- Full re-paint

Used Machines

Used DeHoff 1036 Gundrill

- Drill capacity: 1.00 inch (25.4 mm) diameter

- Slide travel: 36 inches (914 mm)

- Spindle HP: 5 HP

- Spindle RPM: 400 – 6,000 RPM

- Coolant capacity: 300 gallons

- Coolant HP motor: 30 HP

- Coolant HP pump: 60 GPM

- Enclosure covering drill motor, spindle, and drill

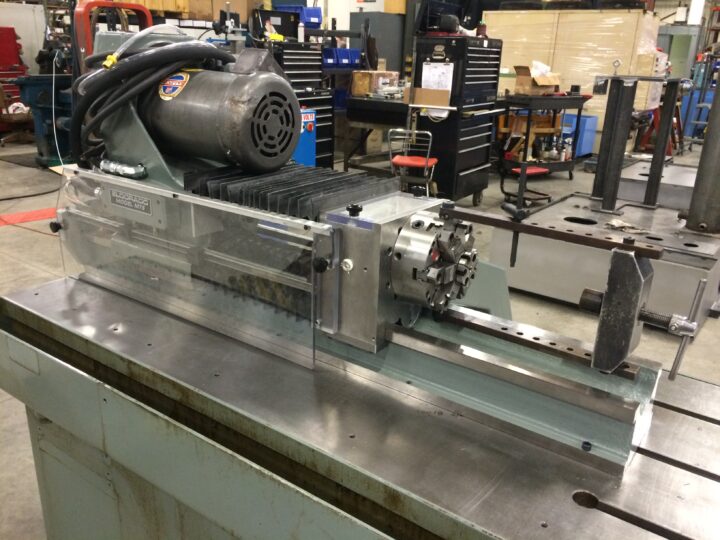

Used Eldorado M60-30 Gundrill

- Drill capacity: 0.125 – 1.000 inch diameter

- Slide travel: 30 inches

- Spindle HP: 5 HP

- Spindle RPM: 800 – 3,450 RPM

- Coolant capacity: 90 gallons

- Coolant HP motor: 5 HP

- Coolant HP pump: 20 GPM

- Workpiece fixturing – Chipbox-mounted 6-Jaw Chuck and Pneumatic Tailstock

- Enclosure covering spindle motor, spindle, and drill

Used TechniDrill 1.00-48 3-Axis BTA

- BTA Drilling Diameter: 1.00 inches

- Drilling Depth: 48 inches

- X-axis Travel: 16 inches

- Y-axis Travel: 10 inches

- Z-axis Travel: 48 inches w/ 1 vibration dampener

- Worktable Dimension: 32” x 26” plus troughing

- Spindle Motor: 15 HP, Infinitely variable speed

- Spindle Speeds: Infinitely variable from 500 – 2,000 RPM in two ranges

- Feeds: Variable from 0.1 – 24 inches per minute, plus rapid

- Chipbox flying bushing: Stroke = 0.5”, capacity = 1.5” gundrill

- Coolant System Capacity: 200 gallons

- Coolant pump motor: 20 HP AC

- Filtration: 10 micron

- Flow rate: 40 GPM max

- Pressure: 1,500 psi max

Used Eldorado M75-15 Gundrill

- S/N 1970

- Year of Mfg = 2000

- Drill capacity: 0.039 – 0.750 inch diameter

- Slide travel: 15 inches

- Spindle HP: 3 HP

- Spindle RPM: 1,440 – 11,500 RPM

- Coolant capacity: 90 gallons

- Coolant HP motor: 7.5 HP

- Coolant HP pump: 20 GPM

- Eldorado Quick-Loc Fixturing System Included (used for round parts w/ on-center holes). Uses a 6-Jaw Chuck on the chipbox with a swing-open pneumatic tailstock.

Used Eldorado M75 Four-spindle Gun Barrel Drilling Machine

- (2) two-spindle machines, (2) coolant systems, (1) shared chip conveyor

- Eldorado M75-48T Gundrilling Machine

- Serial Numbers 1056, 1057

- Two spindles

- 0.750 inch drilling capacity

- 48 inch slide travel

- 3 whip guides per spindle

- F20 coolant system

- Updated controls with touchscreen

- Shared chip conveyor

- Barrel load & unload automation

- Barrel Lengths = 18.5” – 24.5”

- Barrel OD = 1.032” – 1.312”

- Eldorado M75-30T Gundrilling Machine

- Serial Numbers 1058, 1059

- Two spindles

- 0.750 inch drilling capacity

- 30 inch slide travel

- 1 whip guide per spindle

- F20 coolant system

- Updated controls with touchscreen

- Shared chip conveyor

- Barrel load & unload automation

- Barrel Lengths = 10.5” – 18.5”

- Barrel OD = 1.032” – 1.312”